How to choose impact crusher

Impact crushers are versatile, efficient, and widely used in industries ranging from construction to recycling. Selecting the right impact crusher can significantly influence production efficiency, product quality, and operational costs. This guide outlines the key factors to consider when choosing an impact crusher.

1. Understand Your Production Requirements

The first step in selecting an impact crusher is understanding your project needs.

Capacity: Determine the required output. Impact crushers vary in capacity from 50 to 800 tons per hour. For medium to large projects, a machine with higher throughput, such as 200+ tons per hour, may be ideal.

Material Type: Assess the hardness, brittleness, and abrasiveness of your materials. Impact crushers are best suited for medium-hard materials like limestone, gypsum, and coal, but may wear faster with harder materials like granite or basalt.

Particle Size Requirements: Identify your desired output size. Impact crushers excel at creating uniform, cubical particles, which are ideal for aggregate production.

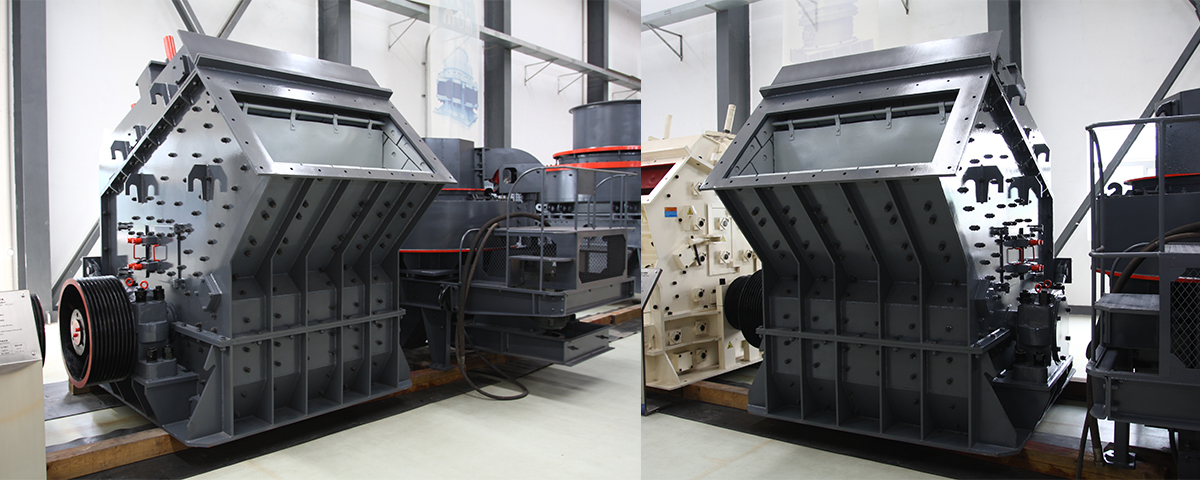

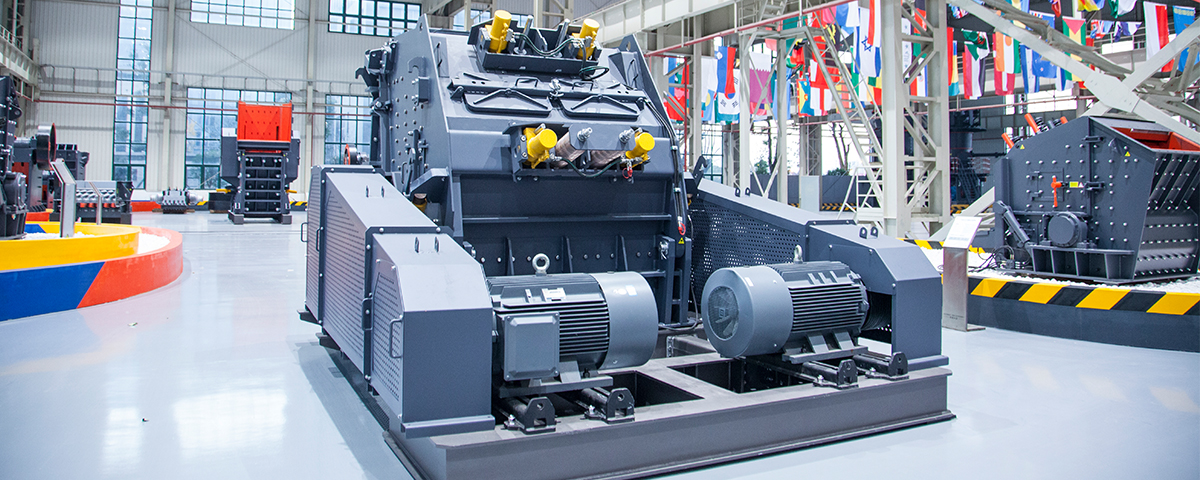

2. Evaluate Crusher Features and Performance

Key features of impact crushers make them stand out in the market.

Superior Particle Shape: Impact crushers produce finer, more consistent particles compared to jaw or cone crushers. This makes them the preferred choice for concrete aggregates and decorative stones.

Efficiency in Secondary and Tertiary Crushing: These crushers handle medium to fine crushing tasks with ease, often following jaw crushers in a production line.

Energy Efficiency: Modern impact crushers are designed to minimize energy consumption while maintaining high productivity.

3. Consider Durability and Maintenance

Wear Resistance: Impact crushers are equipped with components like high-chrome alloy hammers and impact plates to endure wear and tear from medium-hard materials.

Ease of Maintenance: Look for crushers with accessible parts and automated adjustment systems to minimize downtime and maintenance costs.<

4. Match the Crusher to Your Application

Different applications demand specific crusher features.

Construction Aggregates: For creating road base materials, concrete aggregates, and asphalt fillers, choose a crusher with high capacity and superior shaping abilities.

Recycling Projects: Impact crushers are especially effective for processing recycled materials like concrete and asphalt, producing consistent and high-quality aggregates.

Decorative Stone Production: Opt for a machine that delivers precision and uniformity for architectural and landscaping projects.

5. Brand Reputation and After-Sales Support

Choosing a reliable brand ensures quality and longevity.

Brand Expertise: Select manufacturers with a proven track record in impact crusher design and performance.

After-Sales Service: Ensure the brand offers comprehensive support, including spare parts supply, technical guidance, and equipment maintenance.

6. Key Limitations to Keep in Mind

While impact crushers are highly efficient for many applications, they may not be suitable for every scenario.

Higher Wear on Hard Materials: For highly abrasive materials like granite, impact crushers may require more frequent maintenance.

Reduced Efficiency for Harder Rocks: Consider jaw or cone crushers for materials with extreme hardness.

Conclusion: Tailor Your Choice to Your Needs

Selecting the right impact crusher depends on your specific project requirements. Evaluate capacity, material type, particle size, and maintenance needs to identify the best fit for your operation.

Expert Recommendation: SBMX offers a range of high-quality impact crushers designed for optimal performance across diverse applications. Whether you need precision for aggregate production or efficiency for recycling, SBMX’s impact crushers deliver consistent results. Contact us today to explore our solutions and enhance your crushing process!