Jaw crusher Features

- as the primary crusher

- the capacity of the jaw crusher range is about 50ton per hour to 1500 ton per hour

- whether hard stone or soft stone, jaw crusher is also suitable.

- the input size of the jaw crusher range is about 1100mm to 500mm.

Gyratory Crusher Features

- big capacity about 1500 ton per hour to 4500 ton per hour.

- both hard stone and soft stone are all suitable.

- input size is about 1300mm to 1100mm.

- without feeder system with dump truck directly.

Cone crusher Features

- as the secondary or third crusher

- the capacity of the cone crusher range is about 50 ton per hour to 1300 ton per hour.

- the cone crusher is mainly used for the hard or medium hard stone.

- the input size of the cone crusher range is about 400mm to 50mm.

Impact crusher Features

- as the secondary or third crusher

- the capacity of the impact crusher range is about 50 ton per hour to 1000 ton per hour

- the impact crusher is mainly used for the soft or medium hard stone.

- the input size of the impact crusher range is about 500mm to 50mm.

VSI crusher Features

- VSI crusher is usually used for the sand making.

- as the third or fourth step crusher for the shaping stone product.

- the capacity usually range is about 1000 ton per hour to 50 ton per hour.

- input size into the VIS crusher is usually below 50mm.

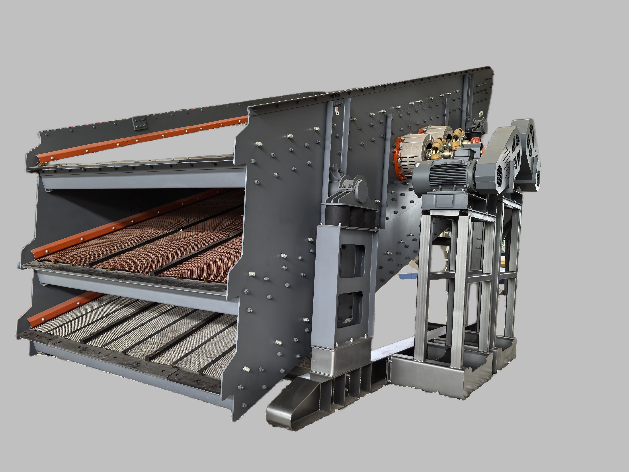

Screen Features

- separate the suitable or qualified product size from the big product size.

- let the bigger size crushed stone return back the crusher again.

- the capacity is about 2000 ton per hour to 50 ton per hour.

- input size to the vibrating screen is Max size 300mm.

Feeder Features

- put the raw materials into the jaw crusher evenly and smoothly.

- make the clay or small stone size drop down directly to the screen or go into the secondary crusher.

- input raw materials size of the feeder is about 1100mm below.

- capacity of the feeder is about 1500 ton per hour to 50 ton per hour.

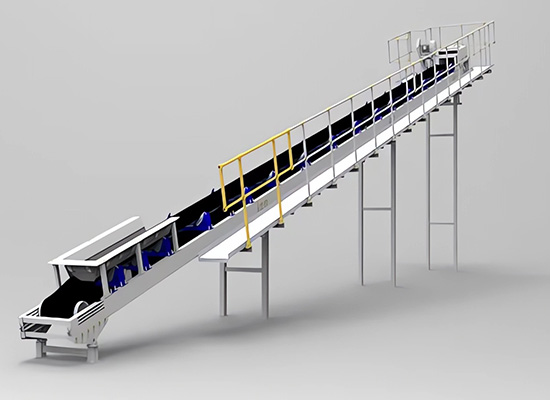

Belt Conveyor Features

- High Efficiency: Smooth and continuous operation ensures fast material transfer, saving time and labor costs.

- Versatility: Suitable for horizontal, inclined, and declined transportation, adapting to various operational needs.

- Durable and Reliable: Built with high-quality materials, offering excellent strength and long-lasting performance.

- Modular Design: Easy to assemble, install, and maintain, reducing downtime and increasing productivity.

- Safety Features: Enhanced protective systems to ensure safe operation in demanding environments.

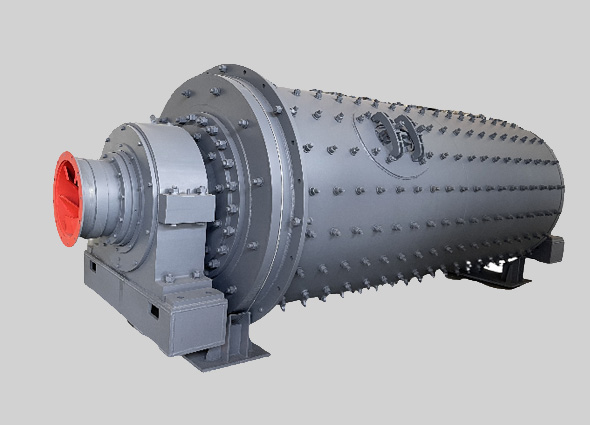

Ball Mill Features

Main Components:

- Feeding section, discharging section, rotating section

- Transmission section (including reducer, small transmission gear, motor, and electrical control system)

Materials and Design:

- The hollow shaft is made of cast steel, ensuring durability and replaceability.

- The cylinder is lined with wear-resistant liners for extended service life.

- The large rotary gear is precision-manufactured using castings and hobbing technology.